The original technique of pattern-welding steel was one born out of necessity. In ancient times, the bloomeries (furnaces) were incapable of producing enough heat to smelt iron and steel into a homogenous mixture hard enough to make a good blade. To fix this, metalsmiths mixed carbon (charcoal) with thin strips of iron in the smelting process and layered these strips onto the softer iron core making a harder, yet more resilient blade.

Modern pattern-welded steel is made from two or more types of steel welded together into a billet. The steel is heated, drawn out, folded over, cut in half and the two pieces welded, again, into a billet. This heating and folding process is repeated until the desired number of layers is achieved (each fold doubles the previous layer count). At this point, the blade is hammered and ground into shape and finally submerged in an acid bath which acts on the different steel layers and draws out the contrasts. This layering of the steel forms the patterning on the blade similar to the original Damascus steel. This is the reason for the label of “Damascus” steel.

But there’s more to Modern Damascus steel than the dramatic patterning on the blade. The functional value of Modern Damascus steel is the formation of a microscopic serrated cutting edge caused by the grinding down of the layers. The forging of Modern Damascus steel is a time-consuming process that requires patience and skill. To pilot a hand-forged Damascus steel blade is like driving a Ferrari: it’s not about getting from start to finish, it’s about enjoying the machine.

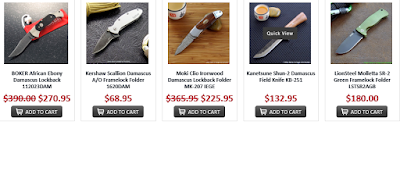

Lionsteel

Lionsteel knives, based in Maniago, Italy, are award-winning cutters with style and substance built with Chad Nichols Damascus and other fine blade steels.

FREE SHIPPING*

On orders of $100 or more

Phone orders

#1-281-747-8781

Lionsteel - Damascussteelknifehub.com